Piezoelectric sound transducer for implantation in an ear

Bimorph structures are a standard method for transforming the high force of piezoelectric materials into a large deflection. Implantable hearing aids mechanically stimulate different parts of the middle ear with the help of miniaturized electromechanical actuators. One possible location to place the actuator is the round-window membrane in the cochlea, which has a diameter in the range of 1 to 2 mm. To realize this engineering problem, an arrangement similar to the image on the right has been developed. It is a piezoelectric actuator with a circular outline, in which unimorph cantilevers are arranged from the actuator’s edge to the center.

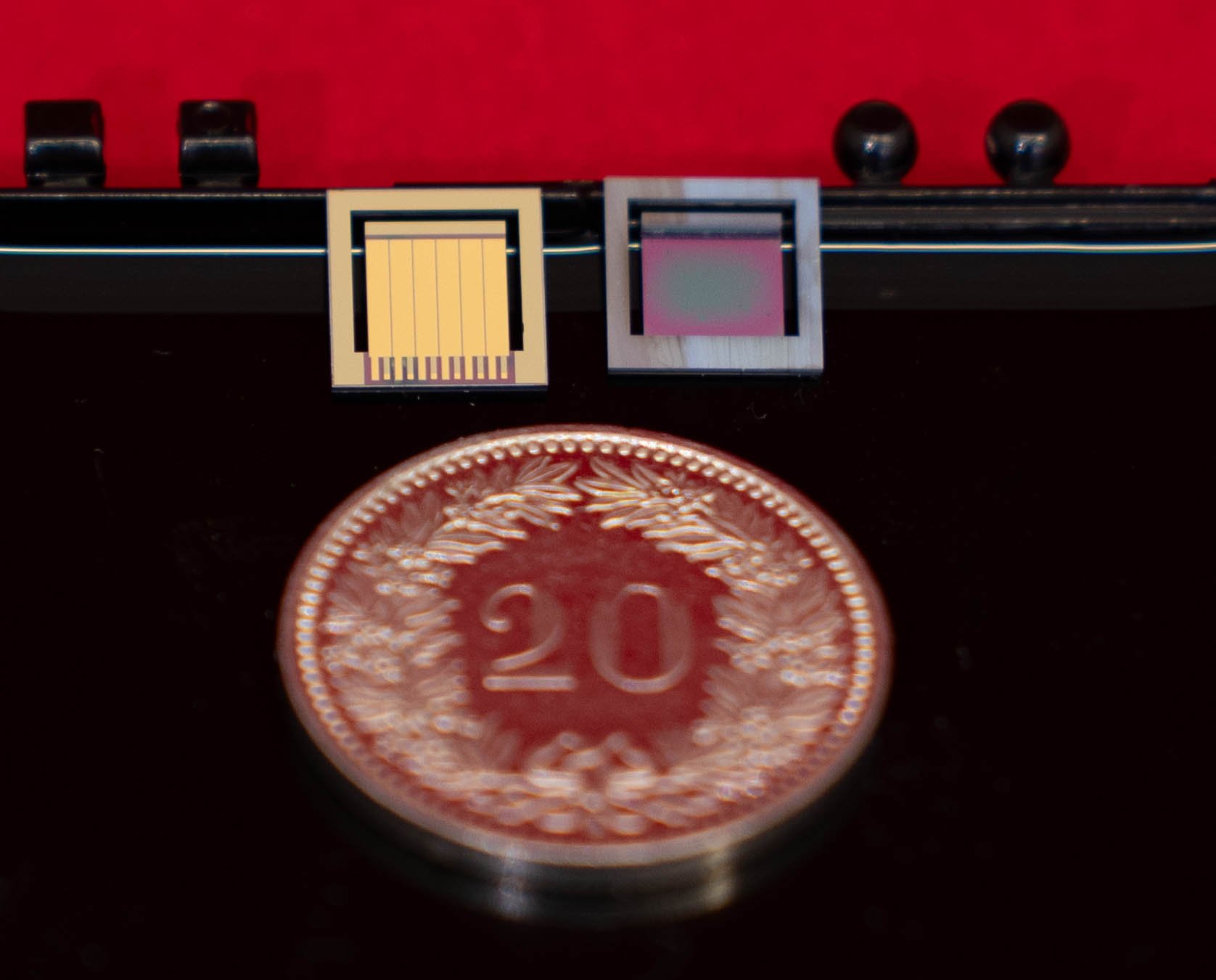

Implant, developed and fabricated by Piemacs.

Our contribution

Design of prototype and micro-fabrication

Performing microfabrication

Deposition of piezoelectric thin films

Characterization of piezoelectric thin film and basic device properties

Energy Harvester

In recent years, piezoelectric energy harvesting from vibrations attracted much attention, also in the field of microsystems. The idea is to provide power to low-power circuits as present in wireless sensors. Devices based on AlN (parallel plate electrode) and PZT (interdigitated electrode) were developed. The advantage of AlN is nevertheless is low dielectric constant leading to a large voltage response. An increase in e31,f e.g. doping with Sc would be very beneficial. One could for instance avoid vacuum packaging in resonant harvesters. Important is, however, to make sure that the dielectric constant does not increase too much. The interdigitated PZT version performs in a similar high output voltage range, however, with a much larger electromechanical coupling coefficient. In other words, the new version can be used in combination with lower quality factor resonant structures.

Our contribution

Designing prototype microfabrication processes

Performing microfabrication

Deposition of piezoelectric thin films

Characterization of piezoelectric thin film

MEMS, developed and fabricated by piemacs.

Piezoelectric Micro-Machined ultrasound transducer array

In a MEMS transducer, the miniaturization requirements impose the use of piezoelectric thin films (S. Trolier-McKinstry and P. Muralt, Journal of Electroceramics 2004), and consequently flexural structures (plate, diaphragm) (P. Muralt et al., MRS Bulletin 2009). The bending of such plates works through the bending moment caused by the piezoelectric stress as the product of the average line force developed in the film, with the distance to the neutral plane of the complete plate (which includes a passive elastic layer of roughly twice the thickness of the piezoelectric layer). The piezoelectric stress is given by the product of the effective transverse piezoelectric coefficient e31,f and the electric field: T1= -e31,f*E3. This coefficient is about 10 times larger in PZT thin films than in AlN thin films. in this project we successfully integrated PZT into pMUT array. In general, PZT is not considered a good material choice for sensor applications, due to high dielectric constant and high dielectric loss. I this project using innovative electrode design, we managed to increase the sensitivity of PZT based array, while benefiting from intrinsic lager piezocoefficient of PZT.

With PZT-based pMUTs, coupling constants of nearly 10% have already been achieved. Higher coupling means the operation voltage can be reduced by at least 50% thanks to the higher piezoelectric coefficient.

MEMS, developed and fabricated by piemacs.

Our contribution

Design of prototype and micro-fabrication

Performing microfabrication

Deposition of piezoelectric thin films

Characterization of piezoelectric thin film and device

Piezoelectric MEMS based loud speaker

One of the main advantages of MEMS-based loudspeakers is their small size. Traditional loudspeakers rely on electromagnetic coils and diaphragms, which can be bulky. MEMS speakers, being miniaturized, are suitable for applications where space is a constraint, such as in portable devices like smartphones, wearables, or hearing aids. MEMS loudspeakers operate based on the movement of tiny mechanical structures rather than the traditional electromagnetic principles used in conventional speakers. The movement can be achieved using piezoelectric materials.

MEMS speakers have the potential for higher precision and faster response times due to the miniaturized nature of the mechanical components. This could lead to better audio quality, especially in terms of clarity and detail.

Our contribution

Process development for prototype micro-fabrication

Performing microfabrication

Deposition of piezoelectric thin films

Characterization of piezoelectric thin film and basic device property

MEMS, developed and fabricated by piemacs.

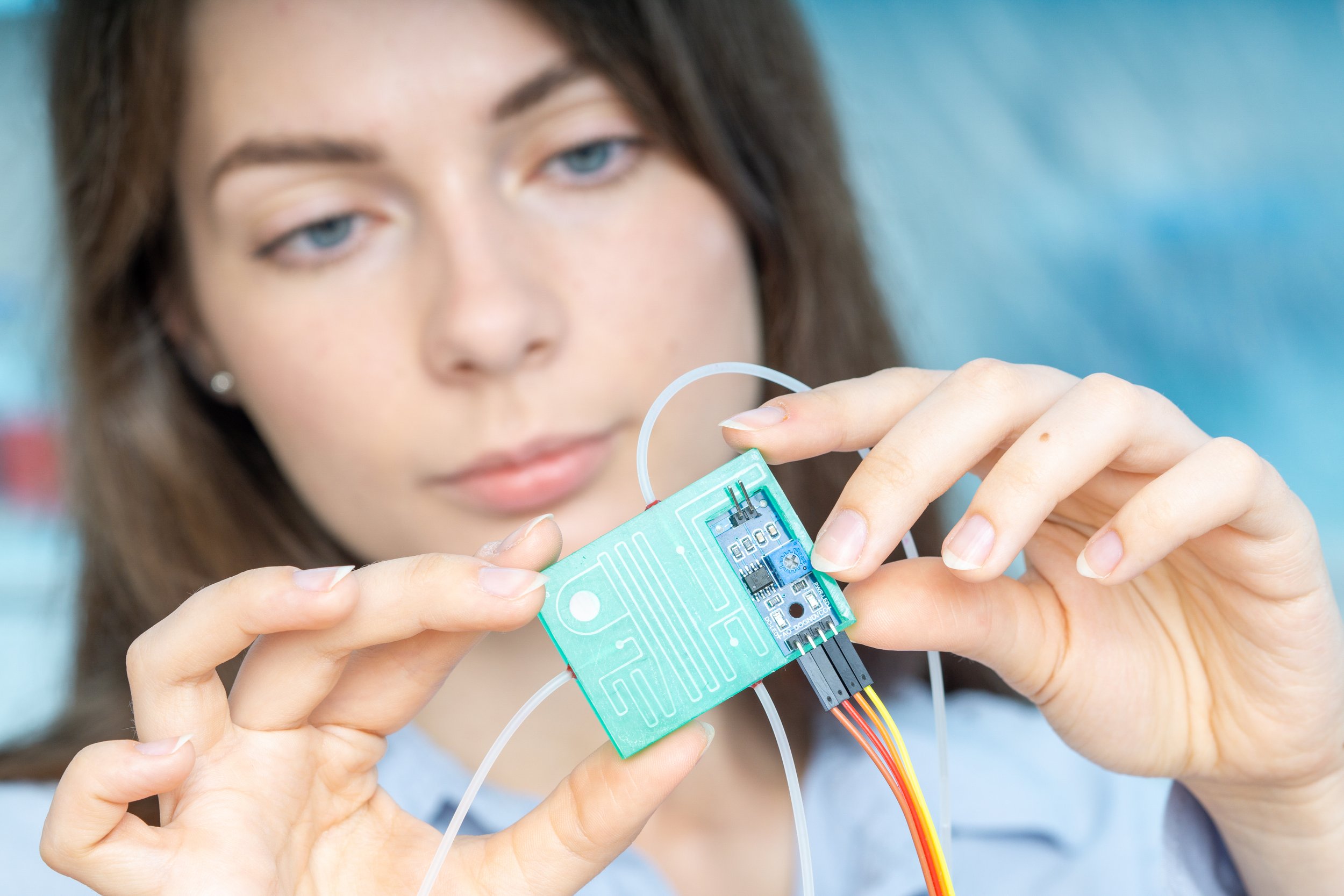

Si/glass micro-fluidic chip for acoustophoresis application

Acoustophoresis is a technique that utilizes acoustic waves to manipulate and control the movement of particles or cells within a microfluidic system. This technology has found various applications in the field of microfluidics, offering precise and non-contact manipulation of microparticles. One of the significant applications of acoustophoresis is in sorting and separating particles. This can be useful in various biological and medical applications, such as isolating specific cells from a heterogeneous sample.

Our contribution

Optimization of the design (Design provided by client)

Performing microfabrication

Deposition of piezoelectric thin films

Characterization of piezoelectric thin film and basic device property

MEMS, developed and fabricated by piemacs.

Particles are focused to the middle of the channel upon generation of acoustic field using a piezo actuator.

Piezoelectric MEMS based pico-projector

Piezoelectric materials exhibit the ability to generate mechanical movement in response to an applied voltage. In the context of pico-projectors, piezoelectric actuators can be used to control the movement of mirrors or other optical components, enabling precise beam steering and focus adjustment. Piezoelectric-based pico projectors offer advantages in terms of energy efficiency compared to traditional projection technologies. The piezoelectric actuators can respond rapidly to changes, allowing for quick adjustments in the projected image.

Our contribution

Optimization of the design (Design provided by client)

Performing microfabrication

Deposition of piezoelectric thin films

Characterization of piezoelectric thin film and basic device property

Membrane pressure sensor

Membrane pressure sensors are typically consist of a flexible membrane that deforms under the influence of pressure. The deformation of the membrane is measured using various transduction methods, such as piezoelectric, capacitive, resistive, or optical, depending on the sensor design. These sensors sensors find applications in a variety of fields, including automotive, medical devices, industrial systems, consumer electronics, and more.

Our contribution

Optimization of the design (Design provided by client)

Performing microfabrication

Deposition of piezoelectric thin films

Characterization of piezoelectric thin film and basic device property

MEMS, developed and fabricated by piemacs.