From Vibration Guesswork to Structural Insight

Surface Vibration ≠ Machine Health

Most condition-monitoring systems rely on accelerometers mounted on the outside of machines.

But surface vibration is fundamentally limited — it is:

Contaminated by environmental and structural noise

Filtered and damped by the machine housing

Delayed in revealing early mechanical damage

Influenced by mounting torque and external forces

Unable to sense internal load paths or stiffness changes

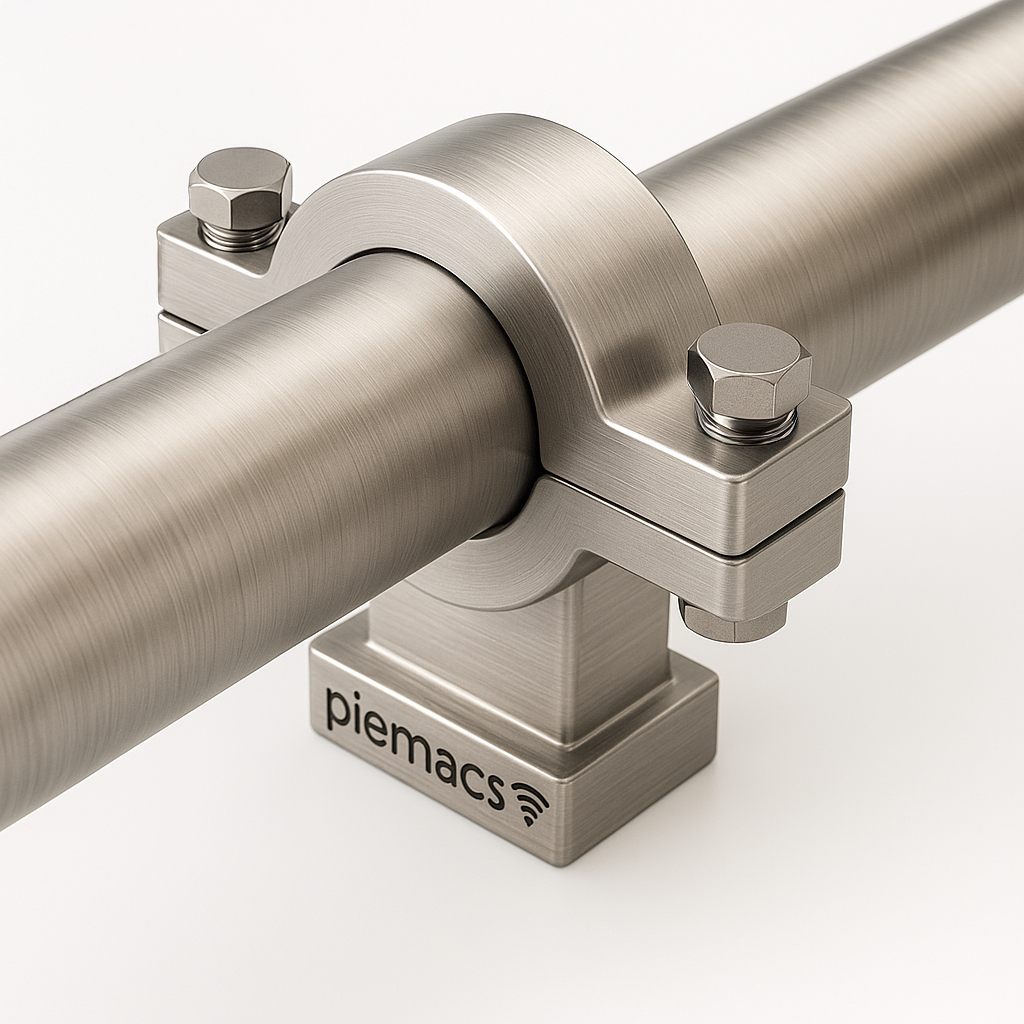

Installed Where Forces Flow

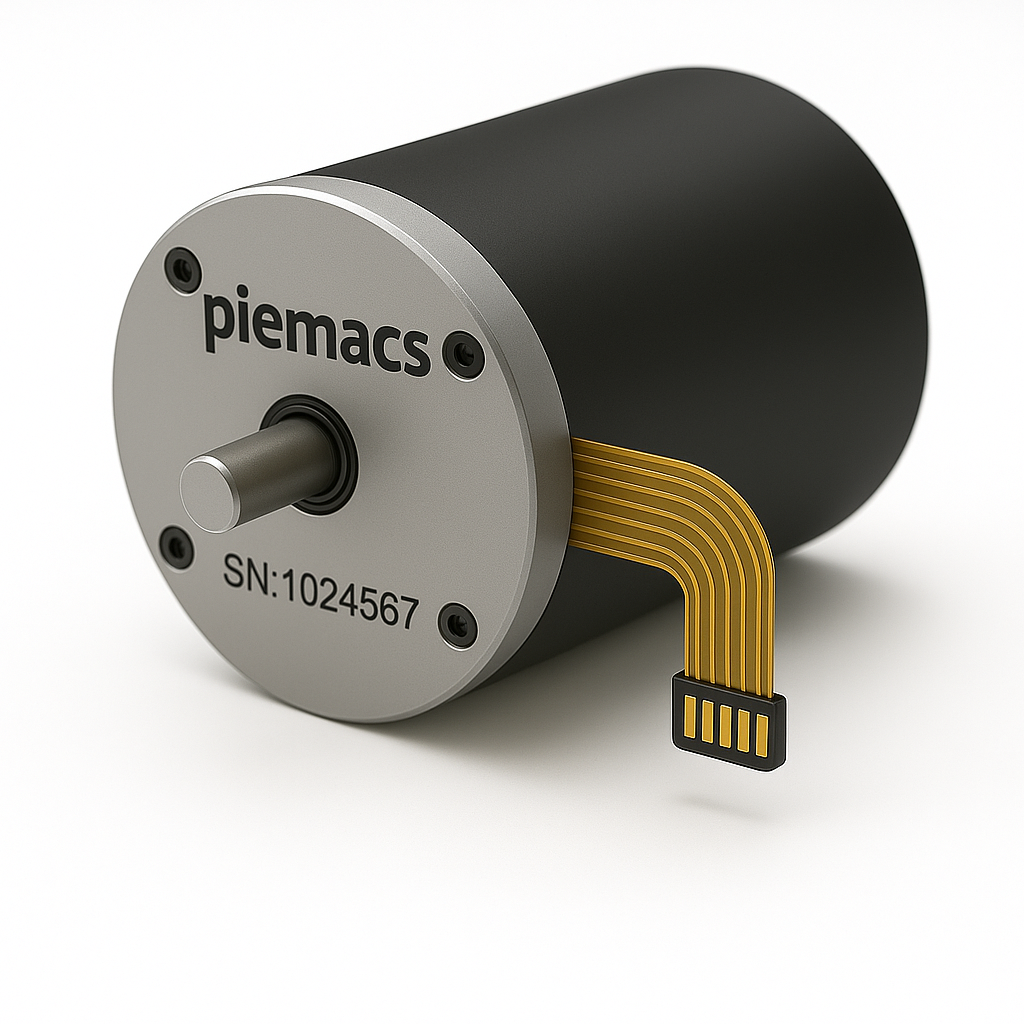

Piemacs sensors mount inside joints, interfaces, flanges, bolts, clamps, and housings — the actual load paths of the machine. Here, the sensor directly measures:

Internal strain energy

Micro-slip between components stiffness changes

Torque and load variations

Early indications of mechanical loosening structural

Resonance patterns

The Advantages of Measuring Structural Strain

Detects failures at their origin — bearing outer-race spalls, preload loss, shaft imbalance, gear mesh anomalies

Noise-immune — only sees internal structural energy, not environmental vibration

Insensitive to mount torque & alignment

Extremely broadband — from mHz structural drift to >20 kHz high-frequency events

No resonance peaks due to zero-mass architecture

Captures stiffness degradation long before vibration amplitude changes

Stable, repeatable baselines ideal for AI/ML models